4 Siting and Installation of Sampling Equipment

4.1 SELECTION OF SAMPLING SITE

Since the intention is to monitor pollutant levels to which people may be exposed, the sampler should be placed where people spend long periods of time, such as residential areas. The method is not recommended for kerbside monitoring by busy roads. The monitoring site must be representative of the local area around it. Some points to bear in mind when selecting a site are listed here.

1. The sampler inlet funnel should be placed where it is exposed to a free flow of ambient air. Avoid situating the inlet funnel in a small enclosed yard, alcove, or corner.

2.The inlet should ideally be situated on whichever face of the building is exposed to the prevailing wind direction.

3. The funnel height should be at least 2.5m, and not more than 5m above the ground or other surface below (such as a flat roof).

4.The funnel should be a horizontal distance of at least 1m from any walls or other structures.

5.The site should not be anywhere near specific local sources of pollution, such as:

individual chimneys, industrial emissions, exhaust vents, areas where bonfires often occur, heavy traffic, vehicles waiting with engines running (for example at traffic lights ), crematoria.

6.The following can interfere with SO2 measurement, and should therefore be avoided:

Toilets, fish shops, baby clinics, school chemistry labs, cleaning fluids, building or demolition work, drains, cattle markets, poultry, manure heaps, fertiliser, sewage works, chlorination plants for swimming pools, trees or foliage close by, any rotting vegetation, moss killing chemicals.

In addition, other factors such as vulnerability to damage, and safe access for funnel installation and maintenance, will need to be taken into account. Also, for long-term monitoring, the future of the site should be considered; are any future changes likely to affect its suitability?

Finding a suitable site is not always easy: AEA Technology Environment will always give advice. The site should be given a unique identification name and number, which will need to be changed if it is moved.

4.2 Location of the sampler

The apparatus needs to be protected from the weather and from extreme temperatures or direct sunlight for long periods. Normally, it is kept inside a building, and the sampled air is drawn in from outside through flexible PVC tubing passing through a hole in a wall or window-frame. The length of tubing between the inlet and sampler should not be more than 6m. With sash windows it may be easier to put a board at the bottom on which the window can rest and through which the hole may be drilled. Alternatively, a glass pane may be replaced by one of Perspex, in which a hole can be drilled. A length of rigid conduit (metal or plastic) should be fixed so that it projects at least 1m from the building and more than 2.5 metres above the nearest large area of horizontal surface such as the ground or a flat roof below. Fig. 4.1 shows the sampling inlet.

The apparatus is best placed in a store-room (although not one where chemicals are stored), or a room not in continuous occupation, as the noise of the pump, though not loud, can be distracting. The noise can be minimised by standing the apparatus on thick rubber or plastic foam sheeting. The sampler requires a mains supply, 240V AC, 50Hz. It is important that the apparatus should be protected from sunlight and from excessive heating by radiators or boilers; sunlight and warmth accelerate the decomposition of hydrogen peroxide, and excessive heating leads to evaporation of the liquid in the bubblers.

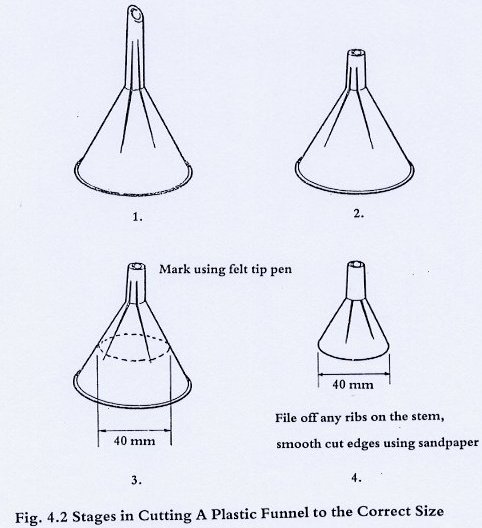

Inlet funnel. It is important that a funnel is used, and that its dimensions are as specified, as this affects the sampling of particulate. The funnel is usually made of plastic (glass was used in the past but is easily damaged). The diameter of the mouth must be 40 mm + 10 mm, and the internal diameter of the stem about 6.5 mm. Most operators buy ordinary plastic laboratory funnels of a larger size, and cut them to the correct size. The mouth of the funnel can be cut carefully using a sharp knife, and any rough edges should be removed using a file or sandpaper. Any ribs on the stem must be filed off to ensure a close fit for tubing, and the stem will also need to be shortened. Fig. 4.2 shows the stages in cutting a plastic funnel to size.

Rigid metal or plastic conduit. This supports the PVC sampling tube, and carries it through the window or wall. At the outer end the funnel is connected, so that outdoor air is sampled. The tubing must extend the whole length from funnel to sampler, inside the conduit. The funnel should have its open end pointing vertically downwards: this can be achieved by bending the conduit itself; however, any bends should have a radius of at least 5 cm. The conduit should be positioned so that the funnel is at least 1m from the building wall, and between 2.5m and 5m from the ground.

Tubing. A supply of flexible PVC tubing will be needed to connect the funnel to the sampler. The tubing must be PVC, not rubber or polythene. It needs to be flexible, but rigid enough to resist kinking; the type sold as "semi-hard" is usually suitable. It may be necessary to select tubing with a slightly larger bore than the sampler’s internal tubing (perhaps 8mm) for this section, if 6.5mm will not fit the funnel or the manifold. A medical grade, such as Portex, is recommended, but not essential.

The sampler should be sited so that the run of tubing is as short as possible, and not longer than 6m. The run of the connecting tubing should be kept as straight as possible without kinks or hanging loops. Where the tubing has to change direction it is essential to keep the radius of the bend at least 5cm. A sharp bend causes turbulence in the air stream and deposition of some smoke particles on the walls of the tubing. Ensure that the tubing is protected from crushing (by furniture or being stepped on). Condensation occurs in tubing which has been chilled as soon as warmer air passes through, and this may reduce the air flow and may also absorb sulphur dioxide if the condensation can collect in any part of the tubing.

When attaching tubing to the funnel, manifold, or any component within the sampler, it is important to make a good seal. There are two methods of doing this.

All tubing should be examined regularly (eg. every two or three months) and renewed when it becomes dirty, sticky, discoloured or loses its flexibility: usually after around two years.

The details of all Network sites are recorded on AEA Technology Environment’s database. This includes:

The site classification code; this describes the nature of the surrounding area. Site codes are as follows:

A1 Residential area with high-density housing (probably terraced), or with medium-density housing in multiple occupation, in either case surrounded by other built-up areas.

A2 Predominantly A1, but interspersed with some industrial undertakings.

A3 Residential area with high-density housing or medium-density housing in multiple occupation surrounded by, or interspersed with, other areas with low potential air pollution output (parks, fields, coast).

B1 Residential area with medium-density housing, typically an inner suburb or housing estate, surrounded by other built-up areas.

B2 Predominantly B1, but interspersed with some industrial undertakings.

B3 Residential area with medium-density housing surrounded by or interspersed with areas with low potential air pollution output (parks, fields, coast), or any residential area with low-density housing.

C1 Industrial area without domestic premises.

C2 Industrial area interspersed with domestic premises of high density or in multiple occupation.

D1 Commercial area or one with predominantly central heating.

D2 Town centre with limited commercial area, possibly mixed with old residential housing and/or minor industry.

E Smoke control area or smokeless zone (the letter to be added to the primary classification).

R Rural community.

O1 Open country but not entirely without source(s) of pollution, eg airfields.

O2 Completely open country; no sources within at least 400 metres.

X Unclassified site, or mixed area.

If any details change, such as Local Authority name or address, site classification or smoke control status, please inform AEA Technology Environment as soon as possible so that our records may be kept up to date. If it becomes necessary to move the sampler, please contact us beforehand for approval of the new site.